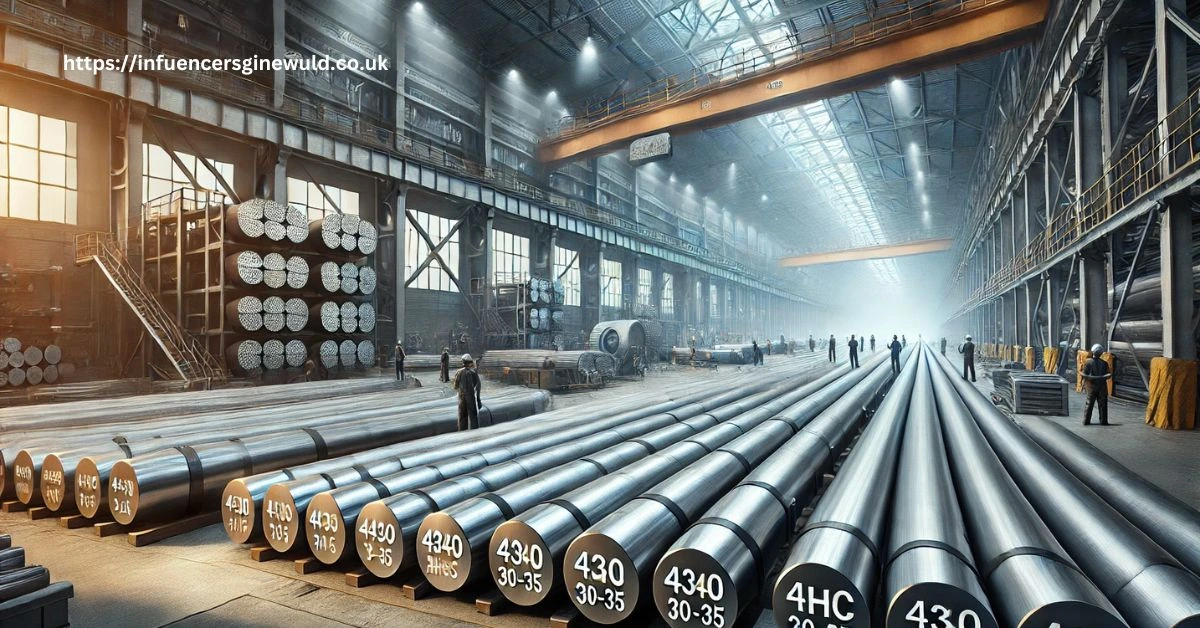

Few high-strength steel options are as versatile and durable as the 4340 RHC 30-35 round bar. Whether you’re in the aerospace, automotive, or oil and gas industries, having a reliable 4340 RHC 30-35 round bar supplier is critical.

This blog post will explain everything you need to know about this material, its properties, applications, and how to choose the best supplier.

What is 4340 RHC 30-35 Round Bar?

4340 RHC 30-35 round bar is a nickel-chromium-molybdenum alloy steel known for its toughness, strength, and wear resistance. After heat treatment, the steel reaches a Rockwell Hardness (RHC) of 30-35, making it ideal for high-stress applications.

The round bar shape is commonly used for parts like shafts, gears, and other components that must withstand heavy loads. A reliable 4340 RHC 30-35 round bar supplier is crucial to ensuring the best quality for your projects.

Why is 4340 RHC 30-35 Round Bar So Popular?

The popularity of the 4340 RHC 30-35 round bar comes from its unique combination of high strength and good ductility. The steel is strong enough to endure heavy wear and tear while being flexible enough to avoid breaking under extreme stress. This makes it the preferred material for the following industries:

- Aerospace: Used in landing gears and other critical parts.

- Automotive: Ideal for components like drive shafts and axles.

- Oil and Gas: Commonly found in drilling equipment.

These industries often rely on trusted 4340 RHC 30-35 round bar suppliers to provide materials that meet strict specifications.

Properties of 4340 Steel

The chemical composition of 4340 steel includes nickel, chromium, and molybdenum, which give the material its high strength and corrosion resistance. The Rockwell hardness of 30-35 makes it suitable for durable parts without becoming too brittle.

Choosing the right 4340 RHC 30-35 round bar supplier can ensure the steel is heat-treated correctly to achieve these properties.

Heat Treatment and Its Importance

Heat treatment significantly enhances the mechanical properties of the 4340 round bar. The process usually involves quenching and tempering, which improve the material’s hardness and toughness.

When selecting a 4340 RHC 30-35 round bar supplier, it’s essential to ensure they provide steel that has undergone the proper heat treatment process. A supplier that offers customization will give you more control over the final product’s performance.

Applications of 4340 RHC 30-35 Round Bar

Aircraft Components: The high strength of the 4340 RHC 30-35 round bar makes it perfect for aircraft landing gears, where the material must withstand extreme pressure.

Automotive Parts: It is commonly used in drive shafts, axles, and other heavy-duty automotive components that need to resist wear and tear.

Oil and Gas: The material’s excellent fatigue resistance and wear properties benefit drilling equipment, including drill collars and bits.

Your choice of a 4340 RHC 30-35 round bar supplier will determine whether the material meets the required standards for these high-stress applications.

How to Choose a Reliable 4340 RHC 30-35 Round Bar Supplier

Here are some tips for finding the best 4340 RHC 30-35 round bar supplier:

- Quality Assurance: Ensure the supplier offers certifications like ISO 9001. This ensures that their goods fulfill global quality requirements.

- Customization Options: A good supplier will offer different sizes and heat treatments based on your needs.

- Global Availability: The best suppliers offer worldwide shipping, ensuring you get your products on time, no matter where your project is located.

Some reputable 4340 RHC 30-35 round bar suppliers include OTAI Special Steel and TW Metals. Both are known for providing high-quality products that meet the needs of various industries.

Advantages of Using 4340 RHC 30-35 Round Bar

- High Strength: Thanks to its composition, 4340 steel offers excellent tensile strength, making it perfect for components that experience high stress.

- Corrosion Resistance: The chromium content in steel helps protect it from rust and corrosion, which is especially important for parts exposed to harsh environments.

- Wear Resistance: The RHC 30-35 hardness ensures the material can withstand continuous wear, making it a long-lasting option for critical components.

Working with a reliable 4340 RHC 30-35 round bar supplier ensures you get these benefits without compromising quality.

Common Sizes and Specifications

Most 4340 RHC 30-35 round bar suppliers offer a range of sizes from 0.375 inches to 10 inches in diameter. The availability of different sizes means you can choose the exact specifications needed for your project. Some suppliers also offer custom sizes and cut-to-length options.

This flexibility makes it easier to source suitable materials for specific applications, and a good supplier will provide comprehensive support to help you find the best option.

Why Choosing the Right Supplier Matters

Not all 4340 RHC 30-35 round bar suppliers offer the same level of service. Choosing a supplier who understands your specific needs can make all the difference in your project’s success.

A reliable supplier will ensure:

- Consistent Quality: Materials meet required specifications.

- On-time Delivery: Parts are delivered when you need them, avoiding delays in your project.

- Customer Support: Good suppliers provide ongoing support and advice to help you choose the suitable material.

Conclusion

If you’re in the market for 4340 RHC 30-35 round bar, finding a trustworthy supplier is critical to the success of your project. This alloy steel is highly valued for its strength, toughness, and wear resistance, making it perfect for high-stress applications.

Choosing a reliable 4340 RHC 30-35 round bar supplier ensures that the material will meet your exact needs. To guarantee the best results, make sure the supplier offers certifications, customization options, and excellent customer support.

Read more blogs at influencersginewuld